With our climate in a state of crisis, looking for alternatives for our currently unsustainable ways of living has never been more important.

But the onus cannot just be on the consumer. Just look at the call to recycle; the eco-friendly burden was placed on the consumer to recycle their products. All the while, big companies continued to overproduce the PET plastic that has polluted our planet in a way that will take centuries to fix. We need change at a business level in order to undo the damage that has been done.

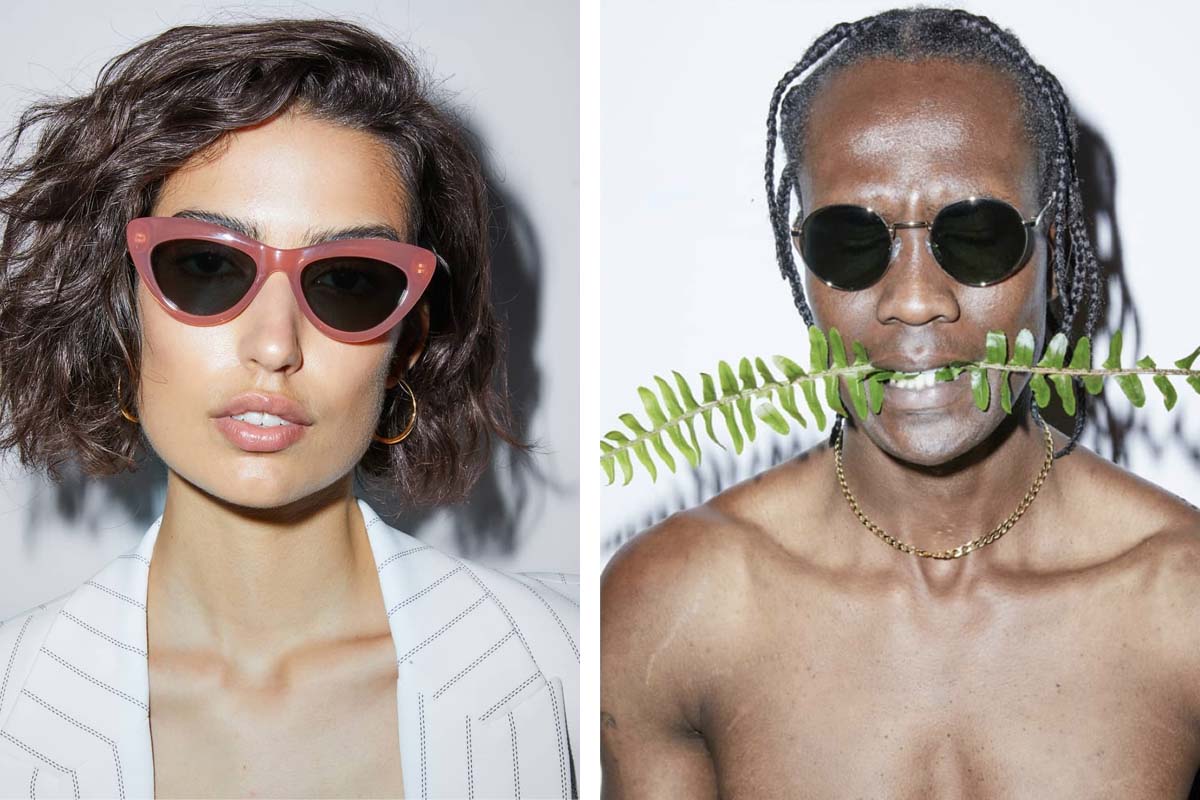

As such, we love to hear about new innovations in the realm of sustainability and brands that are doing the right thing by our collective future. Sunglasses brand Local Supply has moved to manufacturing with an entirely plant-based material. The PET-free resin product is made from beans grown sustainably and ethically - not putting any extra burden on the farm land or taking space from essential food crops.

We spoke with founder Sean Satha on the new sustainability measures the brand is making, how others can do the same and why this has been a five-year long passion project.

Can you tell us a little about the new plant-based frames?

Our entire SS21 range is made using our new signature plant-based resin which is sustainably sourced and produced in Switzerland. The resin is derived from renewable castor bean plants grown in semi-arid areas, not competing with food crops for land. Once the plants are harvested the resin is produced in a facility that’s powered by biofuels.

Why make the decision now to move to plant-based methods for Local Supply frames?

We began testing out plant-based frame materials around five years ago. Unfortunately, back then our first batch of plant-based we made frames wasn’t very good… The materials and technology that we were working with were new – and we’d often change one component of the product and then create an issue somewhere else. So, we've been tweaking the product for several years. Fortunately, the material technology and also our production capabilities have improved a lot during that time.

Last year’s slowdown (due to COVID) gave us an opportunity to implement some major improvements to our products and processes which allowed us to switch to plant-based materials. It was one of the silver linings of 2020 for us - and we’re super proud of where the product is now. I'm sure we'll continue to make improvements in the future too, we’re always pushing ourselves to do better.

By changing these production methods to plant-based and recyclable materials, how much carbon has been saved?

By using this plant-based alternative we produce 50% fewer carbon emissions than equivalent crude-oil based plastics that are typically used in eyewear frames.

Traditional eyewear production is also extremely labour and material intensive, with over 90% of raw material ending up as (typically non-biodegradable and non-recyclable) scrap on the factory floor. To avoid this, we use a custom injection moulding process to produce our frames. Our process makes 10 times more frames per kg of raw material than that of traditional acetate production. This allows for more sustainable, cost-efficient, and waste-free production.

How can these new glasses be ethically disposed of at their end of life?

Our plant-based resin is recyclable. It can actually be recycled using the same recycling equipment as PET - however, the two materials aren’t compatible with each other and can’t be recycled together at the same time.

To make it easier for our customers to ethically dispose of their glasses at their end of life we have a Recycle & Repair Program. It’s a program that we’ve been running for the past few years and it’s super popular.

Essentially, we offer our customers an incentive to encourage them to recycle their old frames with us via our program. When we receive the old frames, we check if we can repair them and if so, we repair the glasses and donate them to a local charity. If they can’t be repaired, we send the glasses to our recycling partner, TerraCycle, where the parts are repurposed & recycled.

Is there a future that includes 100% recycled and recyclable Local Supply products?

Yes - definitely. By the end of this year, all our packaging will be made from recycled, recyclable or biodegradable materials. At the moment, all our products are recyclable. We’re also working on a new range of frames made from recycled and biodegradable materials, which we’ll be releasing later this year.

What can we all do differently when it comes to fashion and accessories to reduce our climate impact?

I think the first step is to be more considerate about your purchases from the outset - and buying from brands that are genuinely making progress in producing more sustainable products. There’s a lot of (often contradicting) information out there about what’s the “most sustainable” option or way of doing things. It can be a bit overwhelming for consumers who just want to buy a cool pair of sunnies - but also want to minimise their environmental impact.

The technology and options available are always changing, but I think a little bit of research can go a long way. So, I think that instead of trying to be perfect if we all do our best to make small steps in the right direction, we’ll make great progress.

What do you think the future of fashion needs to look like?

I think sustainable and ethically made products need to be more accessible and affordable. Unfortunately, I think the idea of “sustainable” and “affordable” products seem a bit mutually exclusive at the moment. Hopefully, increased consumer awareness and demand for sustainable and ethically made products will drive progress in this area and make it more accessible to consumers.

Image: Local Supply